Introduction of AR SAND, the Artificial Sand Made for Casting Molds

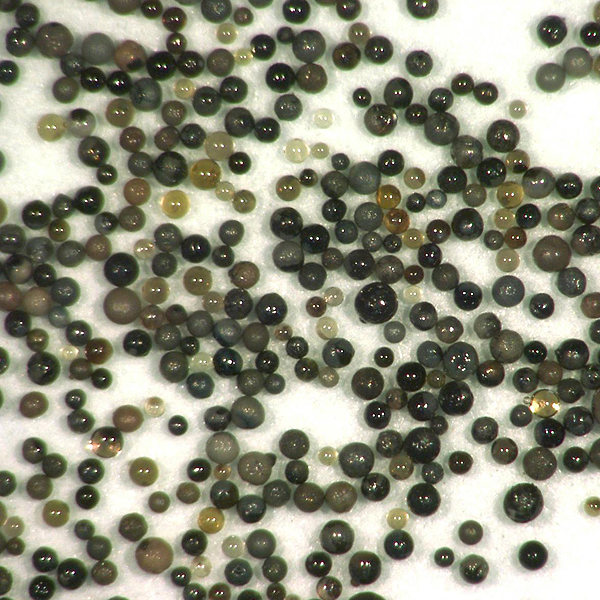

- AR SAND is artificial sand manufactured from high alumina material by an electro-melting and blowing method.

- Suitable for practically any kind of casting mold such as greensand mold, self-hardening mold, shell mold and others, regardless of size.

- Recyclable and Eco-friendly because it does not contain free silicic acid.

Principal Benefits of AR SAND

1. Very high sphericity contributes to excellent fluidity and filling efficiency, resulting in higher mold accuracy and strength.

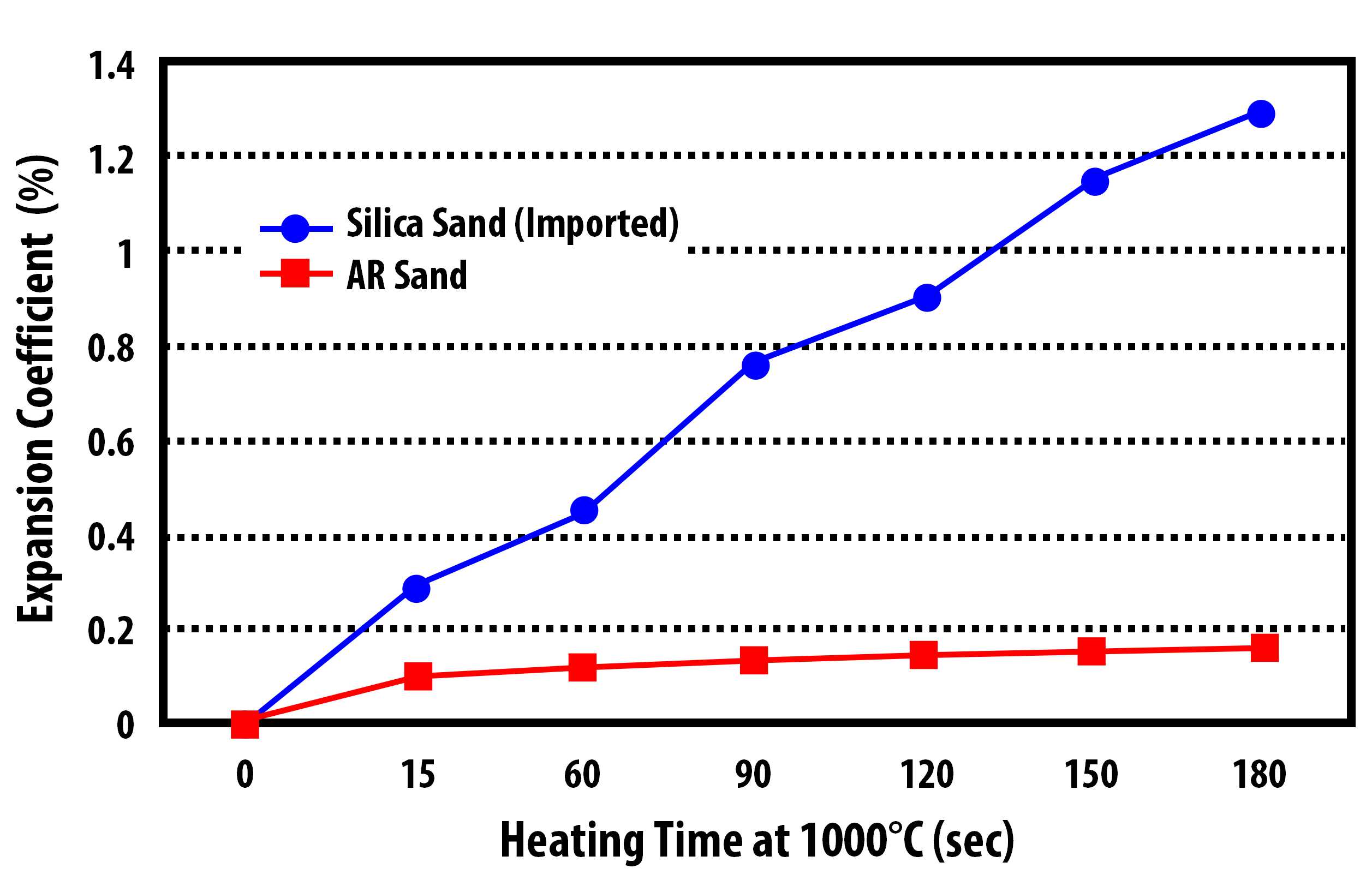

2. Less crush and distortion in mold and improved dimensional accuracy are achieved thanks to low thermal expansion.

3. Superior fire resistance for Mullite-based material.

4. Superior in fracture resistivity and recyclability, enabling reduction of new sand supply and industrial waste.

5. Dust concentration control becomes easy and work environment will be improved, because free silicic acid is not contained.

Specifications of AR SAND

| mesh | 26 | 36 | 50 | 70 | 100 | 140 | 200 | 280 | pan | AFS |

|---|---|---|---|---|---|---|---|---|---|---|

| μm | 600 | 425 | 300 | 212 | 150 | 106 | 75 | 53 | -53 | |

| #350 | 12.7 | 42.8 | 36.5 | 6.3 | 1.3 | 0.2 | 0.2 | 34.5 | ||

| #450 | 7.5 | 34.2 | 25.6 | 15.0 | 11.5 | 5.2 | 0.9 | 0.1 | 44.2 | |

| #650 | 0.1 | 5.8 | 26.7 | 24.3 | 23.5 | 11.4 | 6.6 | 1.4 | 0.2 | 65.1 |

| #750 | 1.9 | 10.0 | 34.8 | 26.2 | 16.6 | 7.5 | 2.4 | 0.6 | 74.0 | |

| #1500 | 0.1 | 3.6 | 10.8 | 49.6 | 29.5 | 6.4 | 161.0 |

| Strength Comparison | AR SAND #650 | Imported Silica Sand | ||

|---|---|---|---|---|

| Amount of Resin (PHS) | 1.2 | 0.8 | 1.5 | |

| Amount of Hardener Agent (PHR) | 20 | |||

| Sand Discharging Temperature (°C ) | 25 | 25 | 25 | |

| Working Life (min) | 6 | 6 | 6 | |

| Compressive Strength / / Bulk Density (N/mm²)/(g/cm³) |

0.5H | 1.2/2.0 | 0.8/2.0 | 0.7/1.6 |

| 1H | 2.0/2.0 | 1.5/2.0 | 1.3/1.6 | |

| 24H | 3.5/2.0 | 3.0/2.0 | 2.6/1.6 | |

※Unit: (N/mm2)/(g/cm3)

| Sand Type | Crush Rate (%) |

|---|---|

| AR SAND #650 | 106 |

| Imported Silica Sand | 206 |

Crush Rate = 100 x (Particle Size Index After Crush / Particle Size Index of Original Sand)

Ball Mill used at 250rpm for 50min.

| Strength Comparison | AR SAND #650 | Imported Silica Sand |

|---|---|---|

| Welding Point (°C ) | 95 | 101 |

| Bend (mm) | 0.9 | 2.1 |

| Cold Strength (N/mm2) | 15.7 | 9.1 |

| Warm Strength (N/mm2) | 3.9 | 1.1 |

| Bulk Density (g/cm3) | 2.1 | 1.5 |

| Internal Hardening (mm) | 4.4 | 4.4 |

Coefficient of Thermal Expansion at 1000°C

ITOH KIKOH CO., LTD. Foundry Division, Sales Group

ADDRESS: Nu-no-wari 412-4, Minamishibata-machi, Tokai, Aichi 476-0001, Japan

TEL: +81 52 604-1216

8:30am to 5:30pm JST on weekdays; except national and corporate holidays

FAX: +81 52 604-1284

This form is A-Form Bamboo for Movabletype Trial version