Contributing to the World Through Casting Products ITOH'S CASTINGS

ITOH KIKOH Co., Ltd.

-

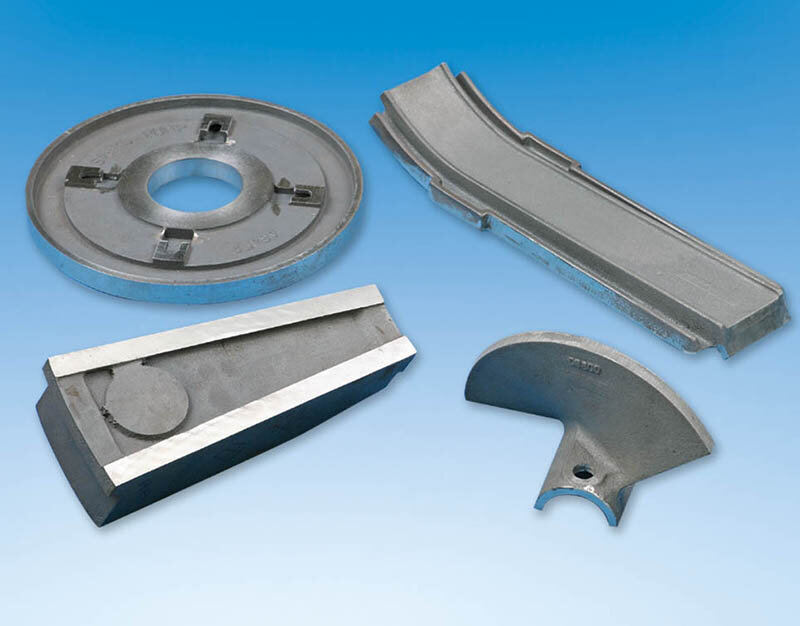

Incinerator Parts for Municipal and Industrial Waste -

Heat Process Tools -

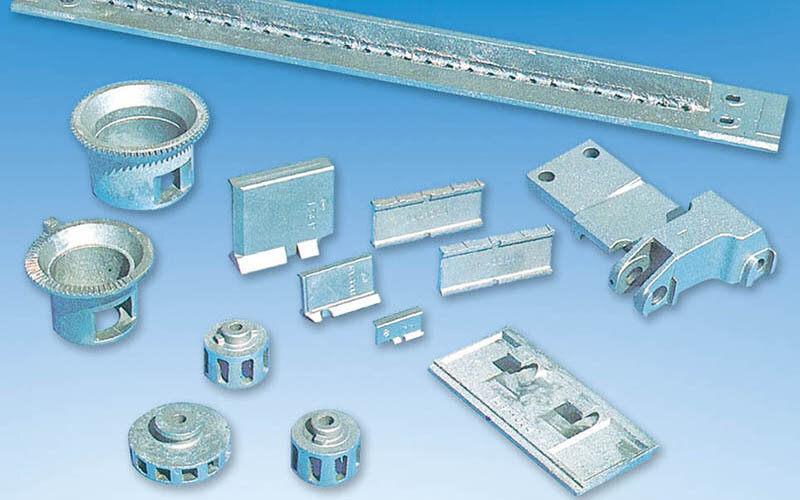

Cast Iron Parts for Shot Blast Machines -

Machine for Valves

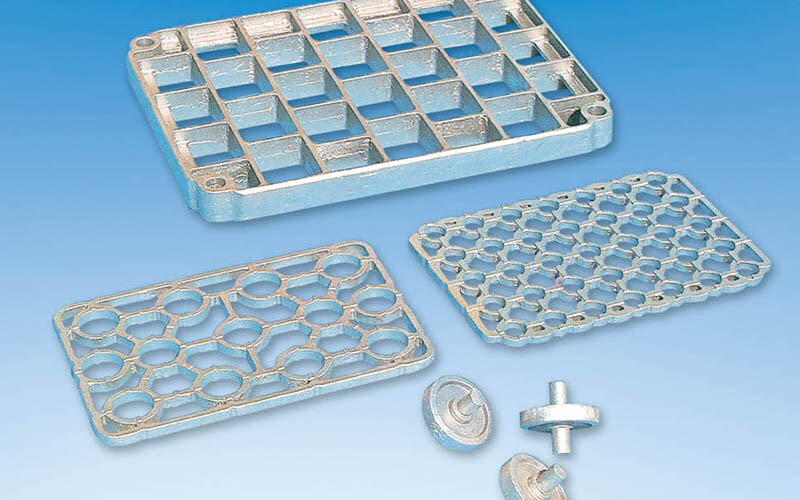

IKK(DALIAN) Co., Ltd.

Manufacturing of high-alloy castings, machining products and fabrication

-

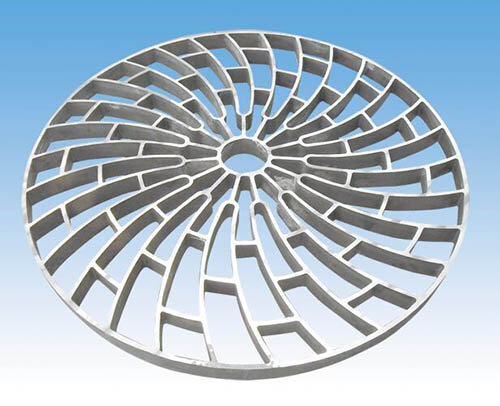

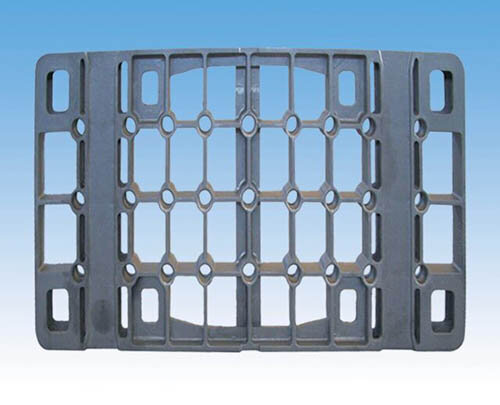

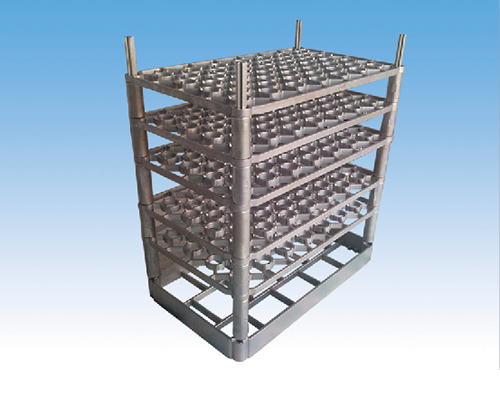

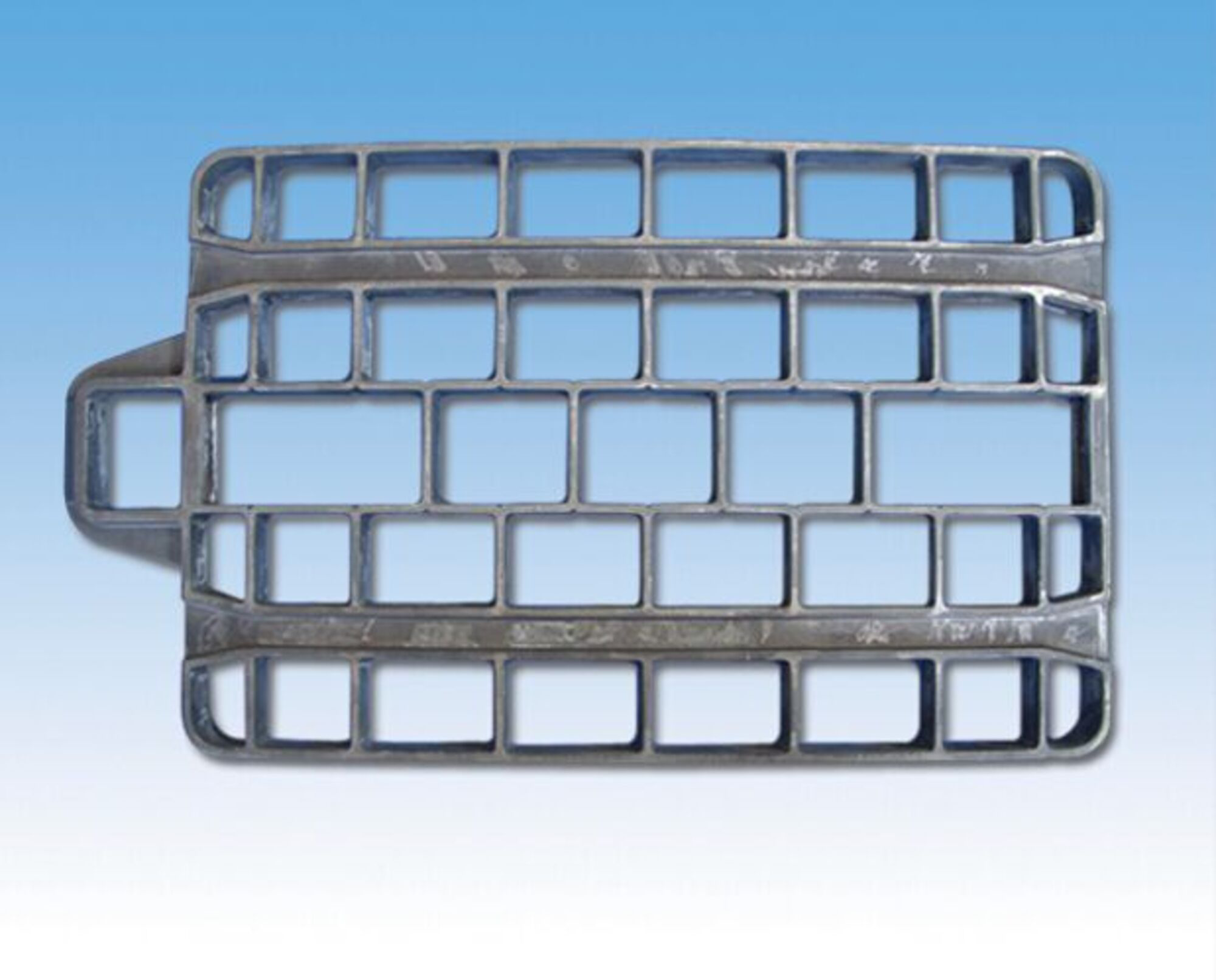

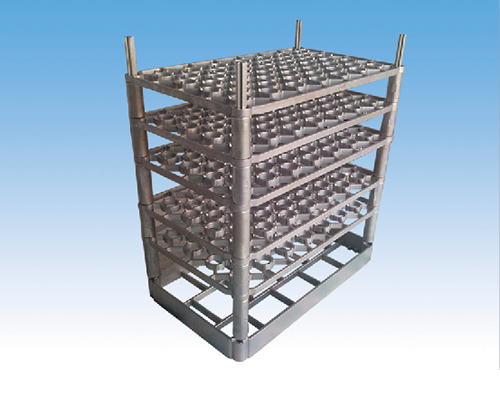

Tray -

Tray -

Tray -

Tray -

Tray -

Tray

Toba-technometal Co., Ltd.

Manufacturing and Sales of High-alloy castings and Centrifugal cast steel pipes

-

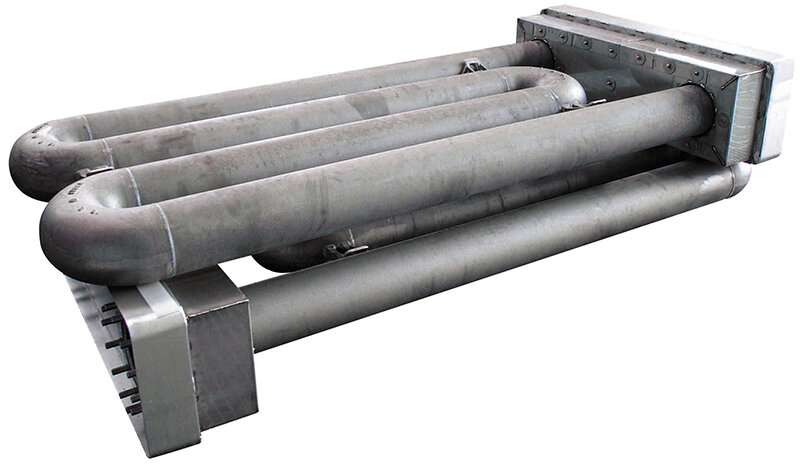

Radiant Tube -

Hearth Roller

ITOCASTING Co., Ltd.

-

Continious Cast Bar(Circle) -

Continious Cast Bar(Square) -

Crane Wheel made of cast steel

-

Chilled Wheels -

Split-tube Coupling -

Flange-type Flexible Shaft Coupling -

Rope Wheel -

Urethane covered Crane Wheel

Advanced casting technology meeting diverse needs

-

- Sand Mold Steel Casting Process Sand Mold Steel Casting Process

We introduced the alkali-Fesneau molding method early on, achieving stable quality through hand-molding each piece individually and establishing a high-mix and low-volume production system, which has been welcomed by a wide range of users.

-

- Shell Mold Casting Process Shell Mold Casting Process

A casting method using thermoset molds, offering higher dimensional accuracy than sand castings and being well-suited for mass production. We meet customer needs by mass-producing products weighing just grams.

-

- Vacuum Molding Process Vacuum Molding Process

This process shapes sand into molds using vacuum pressure. Since no hardening agents are used in the sand, the casting sand can be reused after casting without special treatment, making it an environmentally friendly process.

-

- Lost Wax Investment Casting Process Lost Wax Investment Casting Process

The lost wax casting method, capable of handling lightweighting, dimensional accuracy, and mass production of complex shapes, is used across various fields with a wide range of materials and products.

-

- Horizontal Centrifugal Casting Process Horizontal Centrifugal Casting Process

Using centrifugal casting technology combined with sand casting, we provide distinctive products such as radiant tubes and hearth rollers.

-

- Vertical Centrifugal Casting Process Vertical Centrifugal Casting Process

This casting method utilizes centrifugal force to achieve excellent flow and minimal defects.

-

- Continuous Casting Bar Continuous Casting Bar

We primarily manufacture balls for ball valves, performing all final machining before supplying them to valve manufacturers.

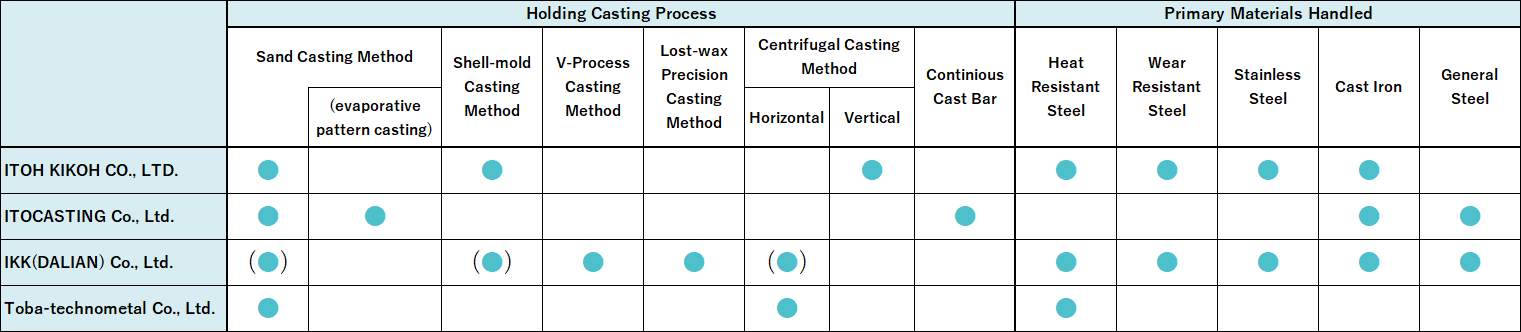

Casting Processes and Primary Materials of ITOH'S CASTINGS Group