IKK Technologies (Introduction of IKK Technology Division)Technology and Testing Center

The Best Available Testing and Management System Serving as the Backbone of IKK “of Technology

To establish corporate-level quality assurance system, ITOH KIKOH Co., Ltd.(IKK) has set up the Test Center equipped with leading edge testing and measuring instruments. With the accuracy IKK gains trust from many customers.

But technical innovation has no end. Accumulated data and know-how serve as the driving force for developing new technologies and for launching new business as well.

Emissions Spectrographic Analyzer

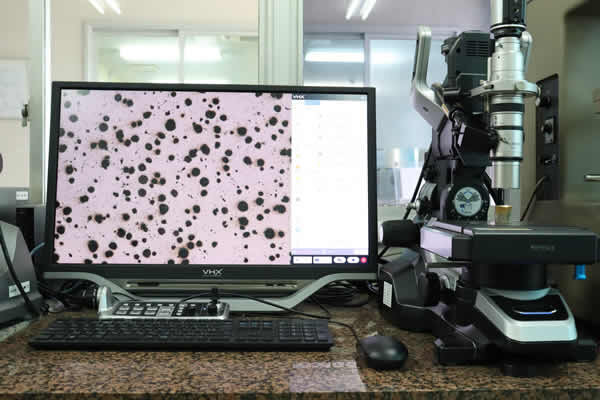

Emissions Spectrographic AnalyzerQuality Assurance Section

The Best Available Testing and Management System Serving as the Backbone of IKK "of Technology

Leading edge testing and measuring instruments including Stress Measurement Device, Emission Analyzer, Micro-hardness Tester, Surface Roughness Tester, etc. Dedicated specialist staff members carry out quality evaluation at every each step in production process such as material control, process inspection and product inspection. And on the occasion of launching new business, the QA section makes the best use of huge amount of data accumulated to this date, being as the core group for new business development.

The Quality Assurance System Indirectly Supporting IKK "of Quality

High-quality manufacturing can be achieved by securing quality in production process. Reliable measuring technology and precise management system of Test Center indirectly supports manufacturing process capability keeping at a high level. From the viewpoint "If you can't measure it, you can't manage it.", IKK's QA section ensures customer satisfaction with visible data, by number of testings and measurements.

Testing and Measurement Equipment

Major Equipment

| Purpose | Equipment・Instrument | |

|---|---|---|

| Chemical Analysis・Composition Analysis | Instrumental Analysis | Optical Emission Spectrometer |

| Carbon・Sulfur Analyzer | ||

| Portable Component Analyzer | ||

| Materials・Mechanical Testing | Hardness | Hardness Testers (Vickers, Rockwell, etc.) |

| Room-Temperature Strength | Universal Testing Machine | |

| High-Temperature Strength | Creep Testing Machine | |

| Physical Property Evaluation | Thermal Properties | Thermomechanical Analyzer (TMA), Thermal Shock Tester |

| Powder Properties | Rotap Sieve Shaker, etc. | |

| Physical Analysis・Metallographic Observation | Surface Analysis | Scanning Electron Microscope (SEM) |

| Morphology Observation | Digital Microscope | |

| Graphite spheroidization rate | Graphite Spheroidization Rate Determination Device | |

| Dimensional Measurement | Surface Roughness | Surface Roughness Tester, Laser Scanning Microscope |

| Dimensional Measurement | Coordinate Measuring Machine, etc. | |

Production Engineering Section

Supporting Foundry Technology by Production Design of Casting Products

Designing casting plan and investigating equipment plan for automotive casting parts from the experimental stage, the PE section repeats improvement in quality and productivity aspects to satisfactory level, accumulating know-how.

Technical System Indirectly Supporting Casting Technology

Being equipped with newest CAD system, optimum casing plan is designed here. Also, the PE section confirms if the casting plan is designed in accordance with the original design by precise measuring instruments, supporting production field.