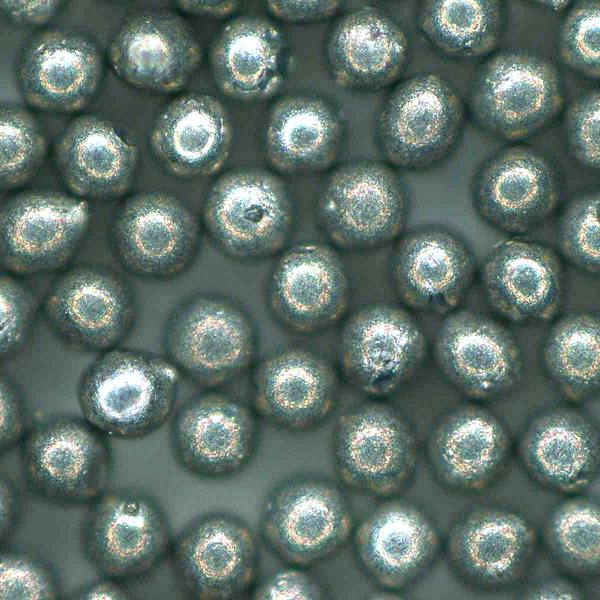

Main Features of Steel Beads

- Ultramicro, spherically-shaped particles made by the Nitrogen Gas Atomizing method.

- Great effect in surface peening for precision metal parts.

Shot peening treatment with Steel Beads will increase strength of metal parts, reducing needs of parts enlargement for strengthening purposes.

Specifications of Steel Beads

| Chemical Composition | C :1.00% Si:1.20% Mn:0.90% |

Particle Size | BPC040:500~300μm BPC050:300~150μm BPC080:200~100μm BPC150:150~ 50μm BPC300:70μm or smaller |

|---|---|---|---|

| Hardness | 700Hv or greater | Packaging Specification | 20kg paper bag /cardboard box |

Typical Applications of Steel Beads

- Peening

- Grinding/Cleaning

- Satin processing and pre-treatment

Also applicable in many other fields.

Measurement Results about Steel Beads

Measured Data of Residual Stress

By shot peening process, a large residual stress is given to 10µm depth from surface.

Measured Chart of Surface Roughness

Surface roughness of approximately Ra 0.2 remains even after shot peening treatment.

ITOH KIKOH CO., LTD. Special Products Division

ADDRESS: Nu-no-wari 412-4, Minamishibata-machi, Tokai, Aichi 476-0001, Japan

TEL: +81 52 689-7531

8:00am to 5:00pm JST on weekdays; except national and corporate holidays

FAX: +81 52 689-2218

This form is A-Form Bamboo for Movabletype Trial version