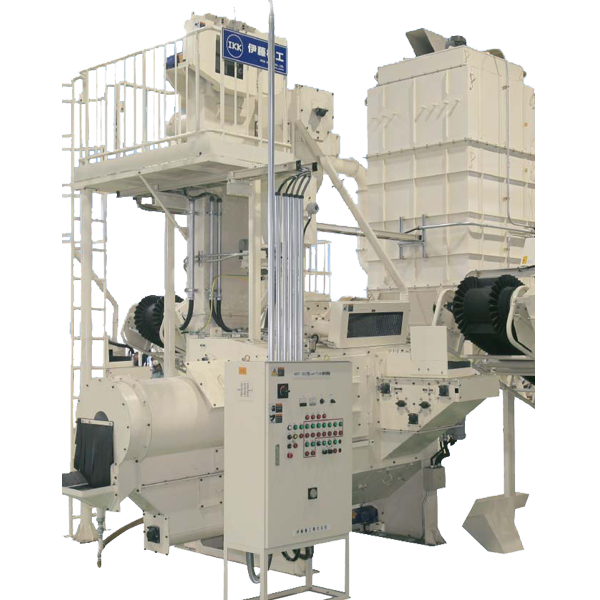

Main Features of IMRT Series

IMRT Series has achieved both robust design and easy maintenance. The Continuous Apron mechanism eliminates the time to open and shut the gates that is required in an ordinary apron type machine case, thus providing a continued operation from loading to discharging after the blasting process. IMRT Series machine is suitable for processing mass-produced products that are not very complex in shape.

Specifications of IMRT Series

| Model # | IMRT1800 | |

|---|---|---|

| Processing Capacity | Capacity | φ600×1560L mm |

| Blasting Units | Number of Units | 1 |

| Maximum Blasting Amount (kg/min) | 230 | |

| Motor (kW) | 15 | |

| Cabinet | Dimension of Projection Chamber (φ×L mm) | 600×1,560 |

Motor (kW) |

2.2 |

|

Dust Collector Air Flow (㎥/min) |

67 | |

Total Output Capacity (kW) |

28.525 | |

Installation Area W x H x L (m) |

4.3×5.2×4.1 | |

Applications of IMRT Series

- Descaling of forged products, heat-treated products, etc.

Optional Features provided for IMRT Series

Upon customer’s request, various kinds of optional features are available such as: conveyor mechanism to load objects and a trommel screen to separate shot particles from burrs.

ITOH KIKOH CO., LTD. Machinery Division

ADDRESS: Nu-no-wari 412-4, Minamishibata-machi, Tokai, Aichi 476-0001, Japan

TEL: +81 52 689-2215

8:30am to 5:30pm JST on weekdays; except national and corporate holidays

FAX: +81 52 689-2218

This form is A-Form Bamboo for Movabletype Trial version