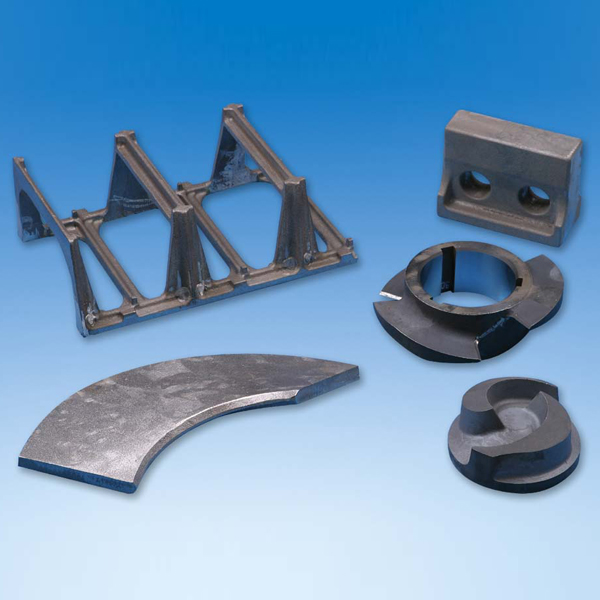

IKK's Casting Parts by Shell Mold Method

IKK’s Casting Products manufactured by the Shell Mold Method make contributions to various categories including the Automotive industry.

Two manufacturing methods -- Dumping and Blowing -- are available at IKK and in the case of specific customers’ needs, IKK adapts more suitable methods to provide quality products.

Shell Mold Casting method is suitable for mass-produced items and small items and can be used for practically any material.

- IKK is well experienced in these fields: automotive parts, pump impellers, tips for asphalt finishers, etc.

Principal Benefits of IKK's Casting Parts by Shell Mold Method

Features of casting products manufactured by IKK’s Shell Mold Casting Method

- Excellent in dimensional accuracy realized by the precision manufacturing method

- Clean casting surface

- Suitable for mass production because mold making is simple.

Features of Mold for Shell Mold Casting

- Casting defect is a rare occurrence because the mold strength is high.

In conclusion, casting products of superior quality are provided by using the shell mold casting method.

ITOH KIKOH CO., LTD. Foundry Division, Sales Group

ADDRESS: Nu-no-wari 412-4, Minamishibata-machi, Tokai, Aichi 476-0001, Japan

TEL: +81 52 604-1216

8:30am to 5:30pm JST on weekdays; except national and corporate holidays

FAX: +81 52 604-1284

This form is A-Form Bamboo for Movabletype Trial version