Principal benefit of Low Flow Micro Shot Peening Machine

By this technology, particulate flux and projection velocity can be controlled only by the gas pressure level of compressed air and consequently, extremely low particulate flux has become available which was not with conventional devices. It is confirmed that by such low level projection, microdimples are built on the surface of the target and additionally, it is possible to give different functionalities such as solid lubricity and oil repellency by affixing submicron particles around the surface of general-purpose steel beads. Microcrystalization of surface part by projection is also possible.

IKK is continuing further technical development in this area including new modification treatment methods to orbital plane of rolling bearing, blade edge of tools and more. Application for drilling to hard-to-work materials like CFRP, by narrowing projection area, will be investigated, too.

Patent issued; No. JP4612095

- low flow projection enabled by newly developed particle conveyance mechanism

- incorporable to existing equipment

- increased applications by lowered flow

- inclined composition layer formed by newly developed particle

- participating “P1” project of industry-academia-government collaboration of Aichi pref. (Japanese only)

Pilot User

- Aichi Science & Technology Foundation “Chi no Kyoten” Lab #305

Specifications of Low Flow Micro Shot Peening Machine

- Rotation speed: 5 - 60rpm

- Horizontal and perpendicular rotations available by setting change of rotation device triaxial adjustable nozzle (manual operation)

- X-axis: 145mm

- Y-axis: 100mm

- Z-axis: 160mm

- projection point checkable by laser pointing

System Configuration

- 1x COP-U3 Main Unit

- 1x Partition

- 1x Compressor

- 1x Dust Collector Unit

- 1x Scale

- Options (supplied from Meijo Univ.)

- 2x Abrasive Tanks

- 1x Spare Tank

Applications of Low Flow Micro Shot Peening Machine

- objects which require low friction and high wear resistance like sliding surfaces

e.g. inner and outer rings of rolling bearings, shaft, working tools (drills, screw-taps, cutting tools, cutting tips - objects which require residual stress without lowering surface roughness

e.g. small gears - objects which require improvement in oil repellency and elasticity by projection adhesion of fine powders only on surface

e.g. crusher tips - hard-to-work objects

e.g. CFRP

Additional Information about Low Flow Micro Shot Peening Machine

Extended Range of Application by Lowered Flow

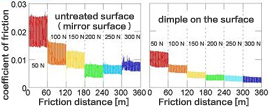

Evaluated by Ring-on-Disc drawing test equipment (ring: FC250, disc: SUJ2 peening process)Friction velocity of 0.1m/sec, adding load by every 60m friction distance, oil viscosity of 20cal@40°C

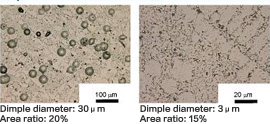

Texture consisting of micrometer range dimples

Microdimples consisting of individual impact marks can be built

A coefficient of friction to be reduced by giving appropriate texture

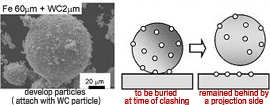

Forming Inclined Composition Layer by Newly Developed Particles

principle of transference of ultrafine particles

Inclined composition technology by low flow peening

ITOH KIKOH CO., LTD. Technology Division

ADDRESS: Nu-no-wari 412-4, Minamishibata-machi, Tokai, Aichi 476-0001, Japan

TEL: +81 52 604-7942

8am to 5pm JST on weekdays; except national and corporate holidays

FAX: +81 52 604-8825

This form is A-Form Bamboo for Movabletype Trial version

Note: Beware of sound.